Innovative mechanical engineering industry support for your specific challenges.

Innovative mechanical engineering industry support for your specific challenges.

Blog Article

Leading Tips for Effective Electrical System Troubleshooting

Troubleshooting electric systems requires a systematic method, grounded in an extensive understanding of electrical concepts and safety protocols. By acquainting oneself with circuit elements, using crucial tools, and sticking to an organized analysis method, professionals can properly recognize and fix problems. Nevertheless, the nuances of reliable troubleshooting extend beyond simple technical understanding; understanding exactly how to record searchings for and prioritize safety and security can dramatically influence results. As we discover these important elements additionally, it ends up being clear that mastering this procedure is not simply useful but necessary for success in the area.

Understand the Essentials

Recognizing the basics of electrical systems is necessary for reliable troubleshooting, as a solid structure allows technicians to identify and resolve problems more successfully. A thorough understanding of electrical principles, such as voltage, current, resistance, and power, is critical in identifying the origin of troubles. Voltage is the electrical potential distinction that drives present through a circuit, while resistance opposes the flow of current, impacting the general functionality of the system.

Experience with circuit components, including resistors, capacitors, diodes, and changes, is also vital. Each component plays a distinct function in circuit actions and can impact efficiency when malfunctioning. In addition, recognizing series and parallel circuit configurations is essential, as these arrangements influence the circulation of voltage and existing within the system.

Technicians must be conscious of potential risks, such as shock and brief circuits, to apply risk-free troubleshooting methods. By mastering these foundational principles, specialists boost their ability to carry out efficient diagnostics and fixings, ultimately leading to improved performance and dependability of electrical systems (electrical system troubleshooting).

Gather Necessary Tools

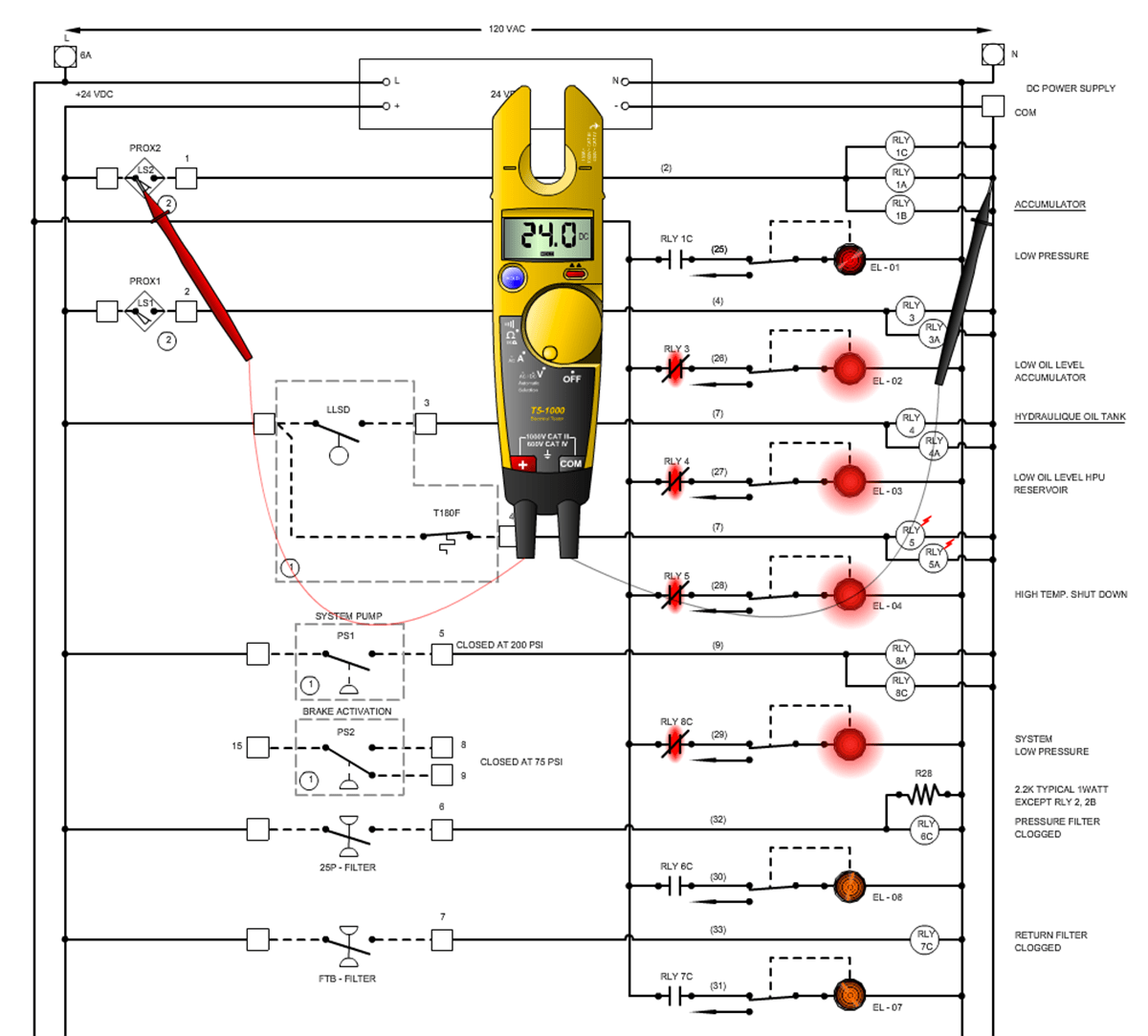

Reliable troubleshooting of electrical systems needs the ideal set of devices to diagnose and fix concerns precisely. Vital devices consist of a multimeter, which determines voltage, current, and resistance, allowing for precise analyses of electrical components.

Additionally, insulated hand devices such as screwdrivers, pliers, and cable pole dancers are essential for safely manipulating electrical connections. It is likewise recommended to have a circuit tester available to verify the presence of voltage in electrical outlets and wires. For more complicated systems, a thermal imaging video camera can assist discover overheating components, indicating possible failings.

Follow an Organized Approach

Having actually gathered the suitable devices, the Discover More Here following action in troubleshooting electric systems is to comply with an organized technique. A methodical method ensures that specialists can identify faults effectively and properly, lessening downtime and stopping unnecessary repairs.

Begin by evaluating the system's schematic representations and requirements. Comprehending the style and operational criteria will certainly provide context for diagnosing problems. Next, isolate the problem location by using a process of removal. This includes monitoring each component systematically, beginning with the source of power and working towards the tons.

Use screening equipment, such as multimeters and oscilloscopes, to collect unbiased data about voltage, current, and resistance at numerous points within the system. This empirical evidence will certainly direct your troubleshooting efforts and help to confirm or get rid of potential causes of failing.

Furthermore, consider environmental variables that may affect the system's efficiency, such as temperature changes or dampness access. A comprehensive examination of circuitry, links, and parts will certainly make sure that all opportunities are you can try these out accounted for.

Paper Your Findings

Thorough documentation is vital in the fixing process of electrical systems. This method not just aids in comprehending the root reason of the problem yet likewise offers as a reference for future repairing initiatives.

Additionally, keeping a log of components changed or fixings executed is invaluable. This details supports stock monitoring and can help examine the durability and integrity of certain parts.

Inevitably, the paperwork process ought to be detailed yet concise, enabling easy retrieval and testimonial - electrical system troubleshooting. By focusing on detailed paperwork, Learn More Here professionals can produce a useful data base that not just aids in present troubleshooting however likewise equips future upkeep efforts, consequently boosting overall system dependability

Prioritize Precaution

Identifying the integral risks connected with electric systems is crucial for making certain security during troubleshooting. Electrical shock, burns, and devices damages are simply a few of the prospective hazards that service technicians face. Focusing on precaution is not just a legal obligation but likewise an ethical necessary that safeguards both the professional and the surrounding atmosphere.

Before beginning any type of troubleshooting task, service technicians must don proper personal protective equipment (PPE), including insulated gloves, safety glasses, and flame-resistant clothing. Making sure that the workplace is completely dry and devoid of clutter can substantially decrease the danger of accidents. Additionally, it is vital to de-energize circuits prior to starting any type of work, confirming that they are not endure the usage of a multimeter or voltage tester.

Developing clear communication protocols with staff member is additionally crucial; this guarantees that every person is aware of prospective dangers and the condition of the electric system being functioned on. Having an emergency situation feedback plan in place can verify vital in the event of an event. By prioritizing precaution, service technicians can efficiently minimize risks and cultivate a more secure workplace.

Conclusion

Efficient electric system fixing counts on a comprehensive understanding of fundamental principles and a methodical strategy. Focusing on safety and security procedures makes certain the well-being of people involved and the integrity of the electrical system.

Report this page